I. Product Features: Precision, Flexibility, and Scalability

1. Multimodal Navigation with Centimeter-Level Positioning Accuracy

Storlogi AGVs support multiple navigation modes, including laser navigation, electromagnetic navigation, and QR code navigation, adapting to diverse scenario requirements. Take laser navigation as an example: it achieves ±1mm positioning accuracy through reflector arrays, ensuring stable operation even in dynamic environments and guaranteeing the precision of material handling.

2. Dynamic Path Planning for Flexible Adaptation to Production Changes

Equipped with an AI decision engine, AGVs can real-time analyze material demands, equipment status, and order priorities to adjust driving routes dynamically. After application in an automotive parts enterprise, the production line’s material response time was shortened by 30%, and the equipment idle driving rate was reduced by 25%.

3. Modular Design for Rapid Adaptation to Business Expansion

The vehicle body adopts a modular architecture, supporting quick addition or reduction of functional modules. For instance, during the Double 11 promotion period, an e-commerce enterprise achieved a daily processing capacity of 100,000 orders by installing temporary shelves and expanding the number of AGVs, and could quickly restore the regular configuration after the event.

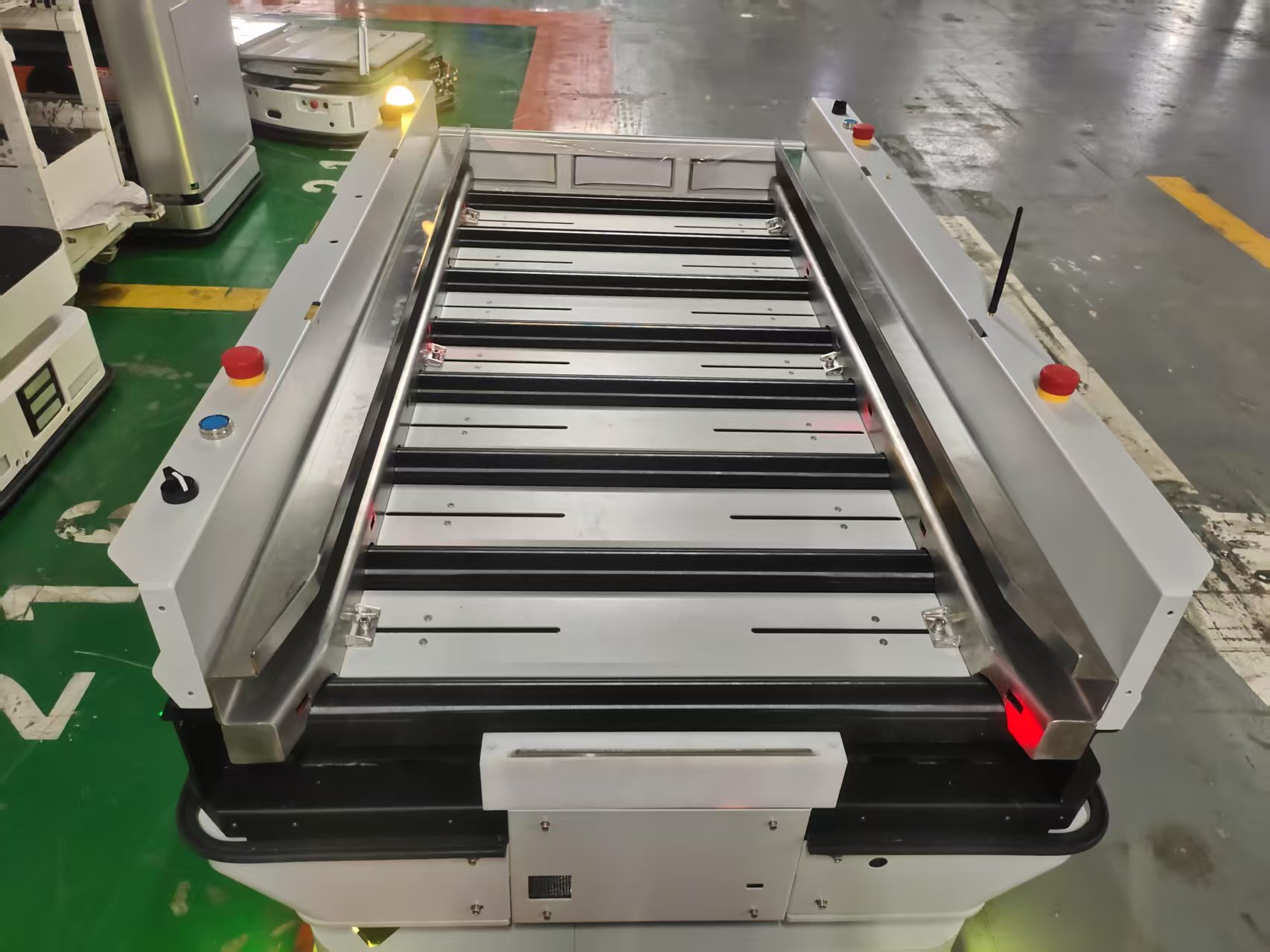

4. Safety Protection System for Human-Machine Collaboration Assurance

Equipped with laser radar, ultrasonic sensors, and emergency stop buttons, it constructs a three-layer safety protection. In the warehouse of a medical device enterprise, when AGVs and manual forklifts work in mixed operations, the collision accident rate is reduced to 0.02%.

II. Product Advantages: Dual-Driven Efficiency Enhancement and Cost Optimization

1. 24/7 Uninterrupted Operation with 40% Efficiency Improvement

Storlogi AGVs can work continuously, automatically docking with charging piles during breaks to ensure non-stop production. After implementation in a food enterprise, cold storage outbound efficiency increased by 40%, with daily order processing capacity surging from 800 to 3,000 orders.

2. 50% Reduction in Labor Costs with ROI Cycle Shortened to 1 Year

Take a cosmetics enterprise as an example: after introducing AGVs, the number of order pickers decreased from 50 to 12, saving over 3 million yuan in annual labor costs. A 15-million-yuan automated warehouse project recouped its investment within 12 months through efficiency gains and cost savings.

3. 25% Improvement in Inventory Turnover and 20 Million Yuan Reduced Capital Occupancy

Through deep integration with WMS systems, AGVs enable precise “goods-to-person” delivery. In a maternal and infant products enterprise, inventory turnover days shortened from 90 to 35 days, the proportion of slow-moving goods dropped from 25% to 8%, and over 20 million yuan in inventory funds were released.

4. 15% Energy Consumption Reduction in Compliance with ESG Standards

Equipped with permanent magnet synchronous motors and energy recovery systems, a cold chain logistics center saved over 1.2 million yuan in annual electricity costs, reduced carbon emissions by approximately 400 tons, and helped the enterprise obtain over 800,000 yuan in green supply chain subsidies.

StorLogi

StorLogi