In the Industry 4.0 era characterized by the deepening of global trade and the accelerated penetration of digital technologies, the warehousing and logistics link has broken through the single attribute of traditional “goods storage and transshipment” and evolved into a core hub connecting manufacturing, commercial circulation and terminal consumption. As an indispensable key node in the supply chain system, the operational efficiency, management level and collaboration capability of modern warehousing centers directly determine an enterprise’s market response speed, cost control precision and customer service quality. Today, relying on standardized management systems, intelligent technology applications and three-dimensional spatial layout, a new generation of warehousing centers is breaking the bottlenecks of traditional operations. With the core characteristics of “efficiency, precision, safety and flexibility”, they provide a solid support for the optimization and upgrading of the entire supply chain link, and drive the high-quality development of the industry towards digitalization, intensification and collaboration.

I. Three-Dimensional Layout and Spatial Empowerment: Resolving the Core Contradiction Between Warehousing Capacity and Operational Efficiency

Traditional warehousing models generally face pain points such as low space utilization, chaotic operational flow lines and slow cargo turnover, making it difficult to adapt to the operational demands of large-scale production and high-frequency orders. Through scientific three-dimensional layout design, modern warehousing centers realize the maximization of space resource utilization and the optimization of operational process configuration, fundamentally resolving the dual problems of capacity and efficiency.

- Refined Spatial Planning: Adopt a composite layout of “heavy-duty shelves + automated storage and retrieval system (AS/RS)” to fully develop vertical space and finely divide horizontal areas, achieving a vertical utilization rate 3 to 5 times that of traditional flat warehouses and significantly saving land costs. Divide dedicated modules such as profile areas, auxiliary material areas and finished product areas according to cargo characteristics including weight, volume and turnover rate. Combined with “letter + number” coding, electronic shelf labels and barcode traceability technology, operators can quickly locate cargo via handheld terminals, improving order picking accuracy and efficiency by more than 60% compared with traditional models and avoiding problems such as wrong delivery, missing delivery and cargo backlog.

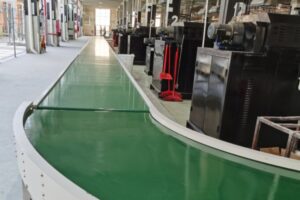

- Rationalized Matching of Flow Lines and Equipment: Follow the principle of “one-way flow and efficient connection” to plan a three-level flow line network consisting of main passages, auxiliary passages and operational passages. Standardize the movement trajectories of personnel, cargo and equipment through ground markings, signboards and intelligent guidance systems to avoid congestion and interference. Introduce automated equipment such as Automated Guided Vehicles (AGVs), intelligent forklifts and robotic arms to realize semi-automated/automated operations throughout the entire process. AGVs can independently transfer cargo across regions, improving cargo transshipment efficiency by more than 40% and adapting to scenarios of large-batch and high-frequency turnover. Equip with temperature and humidity control, fire and explosion prevention equipment to ensure the storage safety of special cargo and meet industry compliance requirements.

II. Full-Process Standardized Management: Building a Standardized and Controllable System for Warehousing Operations

The efficient operation of modern warehousing centers cannot be separated from the support of a full-link and standardized management system. The so-called standardized management refers to formulating unified, standardized and implementable operating procedures and management standards around all links of warehousing operations, realizing full-process control, traceability and optimization from cargo warehousing to outbound delivery, minimizing human errors and improving operational stability and reliability.

- Implementation of Packaging Standardization: Select suitable packaging materials and methods according to cargo characteristics – reinforce long-strip cargo with high-strength strapping and protective sleeves, and package small pieces of cargo with standardized corrugated cartons/plastic turnover boxes. Clearly mark cargo information, shelf life and storage requirements on the boxes, and affix warning signs such as moisture proof and crush proof. This not only reduces cargo damage rate and improves the neatness of transshipment, but also lays a foundation for the operation of automated equipment.

- Standardization of Operational Processes: Formulate the SOP Operation Manual for Warehousing Operations, clarifying the operating standards, responsibility division and assessment indicators for core links such as warehousing inspection, putaway storage and order picking review. Conduct a one-by-one verification of cargo and documents during warehousing, and record information into the Warehouse Management System (WMS) through barcode scanning. Implement a three-level verification process of “picking – review – packaging” after order picking, record data throughout the entire process to achieve traceability, and control the operational error rate within 0.3%.

- Comprehensive Safety and Compliance Control: In terms of hardware, shelves adopt anti-toppling design, passages are equipped with anti-collision guardrails, emergency lighting and a complete fire protection system with regular inspection and maintenance. In terms of management, standardize equipment operating procedures, carry out pre-job and regular safety training, and strictly prohibit non-compliant operations. For special cargo, strictly follow national standards such as GB 15603-2022 and GB/T 27924-2011, establish a traceability system and safety emergency plans to achieve “zero safety accidents and zero compliance risks”.

III. Empowerment of Intelligent Technologies: Driving the Transformation of Warehousing Management Towards Digitalization and Precision

The in-depth application of digital technologies is the core feature that distinguishes modern warehousing centers from traditional ones. Relying on the collaborative linkage of digital tools such as the Warehouse Management System (WMS), Enterprise Resource Planning (ERP), Manufacturing Execution System (MES) and Transportation Management System (TMS), warehousing centers realize full-process digital control of inventory management, operational scheduling and data statistics, greatly improving the precision of management and the scientificity of decision-making.

- Empowerment of the Core WMS: Undertake functions such as cargo information management, real-time inventory monitoring, operational scheduling and data statistics, realizing real-time update and visualization of inventory data. Automatically issue replenishment and near-expiry warnings, optimize order picking paths and resource allocation, and generate multi-dimensional reports, providing accurate data support for management to optimize strategies and adjust inventory structure.

- In-Depth Collaborative Linkage of Multiple Systems: Connect with the MES to complete material sorting and preparation in advance, supporting Just-In-Time (JIT) production, shortening lead time and reducing the cost of material backlog. Link with the ERP to synchronize order information in real time, adjust outbound order by priority, predict demand combined with big data, and stock popular products in advance to achieve “delivery within 48 hours”. Connect with the TMS to seamlessly link outbound and transportation plans, match the optimal logistics solutions and track in real time, improving logistics timeliness by more than 30% and reducing transportation losses.

- Iterative Upgrading of Emerging Technologies: Internet of Things (IoT) sensors collect real-time data such as storage environment, equipment operation and personnel location to achieve precise perception of all elements. Big data analysis deeply mines operational, inventory and order data to optimize resource allocation and operational processes. Artificial intelligence (AI) technologies empower intelligent sorting robots and automatic inventory systems to realize fully automated operations, reducing labor costs and error rates.

IV. Supply Chain Collaboration Empowerment: Creating the Core Value of a Flexible Warehousing Hub

Against the backdrop of increasingly diversified and personalized market demands and an accelerating supply chain rhythm, modern warehousing centers are no longer independent storage units, but flexible hubs in the supply chain collaboration network. Through in-depth linkage with upstream and downstream links, they realize the optimal allocation and efficient flow of supply chain resources, and enhance the resilience and competitiveness of the entire supply chain.

- Win-Win Collaboration with Upstream Suppliers: Build a supplier collaboration platform to share information such as purchase orders, delivery plans and inventory status, helping suppliers arrange production and delivery rationally. Implement the Vendor Managed Inventory (VMI) model, where suppliers are responsible for inventory management and replenishment of some materials, and the warehousing center is only responsible for storage and distribution, reducing the enterprise’s inventory costs and procurement risks and ensuring the stable supply of materials.

- Upgrading of Downstream Customer Services: Customer demand-oriented, provide personalized warehousing and delivery services – set up exclusive areas and priority outbound delivery for key customers, and offer centralized packaging and consolidated transportation for small-batch orders. Link with the Customer Relationship Management (CRM) system to grasp demand changes and feedback, optimize strategies and processes in a timely manner, extend value-added services such as cargo inspection, customized packaging and labeling, and provide one-stop logistics solutions.

- Cross-Regional Warehousing Collaborative Linkage: Build a national/global warehousing network relying on digital technologies, and uniformly control inventory and operational information of each node through the WMS. Allocate cargo across regions to balance inventory according to regional demand differences and order distribution, improving market response speed and enhancing the supply chain’s anti-risk capability in response to emergencies.

V. Future Trends: Digitalization, Greenization and Intelligence Leading the New Development of the Warehousing Industry

With the continuous iteration of technologies and the continuous upgrading of industry demands, modern warehousing centers will develop towards greater digitalization, greenization and intelligence, constantly reconstructing the model and value of warehousing operations.

- In-Depth Digitalization: Digital twin technology will be widely applied in warehousing planning, construction and operation, simulating and monitoring the entire process through virtual models to improve management precision and efficiency.

- Comprehensive Greenization: Increase investment in environmental protection, adopt green packaging, energy-saving equipment and new energy logistics vehicles, optimize layout and operational processes, reduce energy consumption and carbon emissions, and practice sustainable development.

- Ultimate Intelligence: AI and robot technologies will be fully popularized to realize fully automated and unmanned warehousing operations; 5G technology will support real-time equipment linkage and high-speed data transmission, building an intelligent warehousing ecosystem.

Taking Warehousing Upgrading as the Fulcrum to Unleash Value Enhancement Across the Entire Supply Chain

The construction and operation of modern warehousing centers serve as a pivotal driver for enterprises’ digital transformation and supply chain optimization. From the scientific planning of three-dimensional space and standardized management of the entire process, to the in-depth empowerment of intelligent technologies and collaborative linkage of the supply chain, a new generation of warehousing centers, through all-round upgrading, is breaking the boundaries and bottlenecks of traditional operations and emerging as a key force driving the efficient operation of the supply chain and enhancing enterprises’ core competitiveness.

In the future market competition, only by continuously deepening the refinement, digitalization and intelligence of warehousing management, and steadily strengthening the supply chain collaboration capability of warehousing centers, can enterprises better adapt to market changes, meet customer demands, maximize the value of the entire supply chain, and lay a solid foundation for their high-quality development. Meanwhile, driven by technological innovation and model transformation, the warehousing industry will step into a new era of greater efficiency, green development and intelligence, providing crucial support for the stability and upgrading of the global supply chain.

StorLogi

StorLogi