Building the Backbone of Modern Warehousing: High-Rise Racking System Construction in Progress

As global supply chains evolve toward higher efficiency and automation, the demand for large-scale, high-density warehousing systems continues to rise. The project shown here represents a new generation of industrial storage infrastructure—an extensive high-rise racking system engineered to support automated and semi-automated logistics operations.

A Large-Scale Structural System Taking Shape

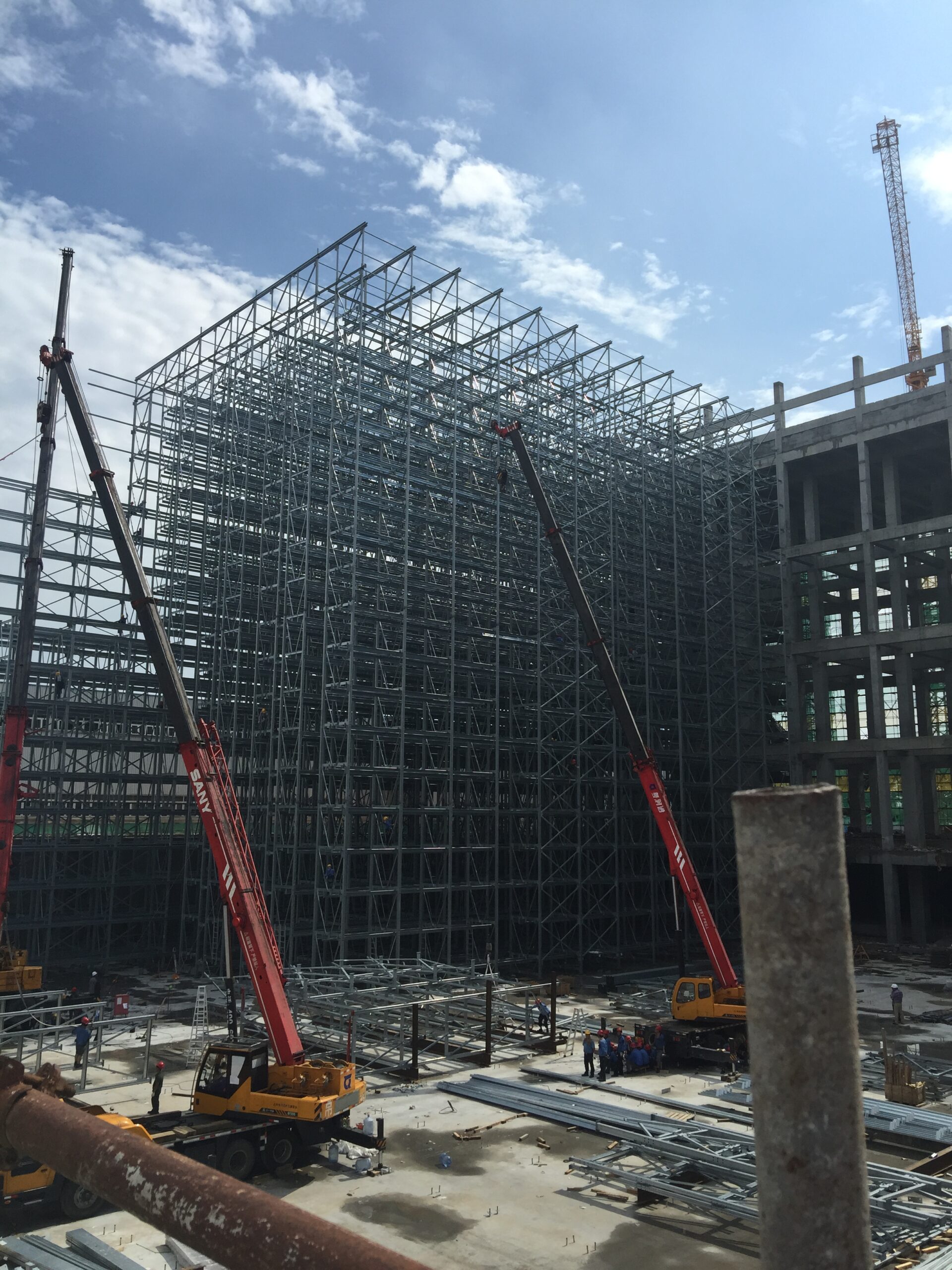

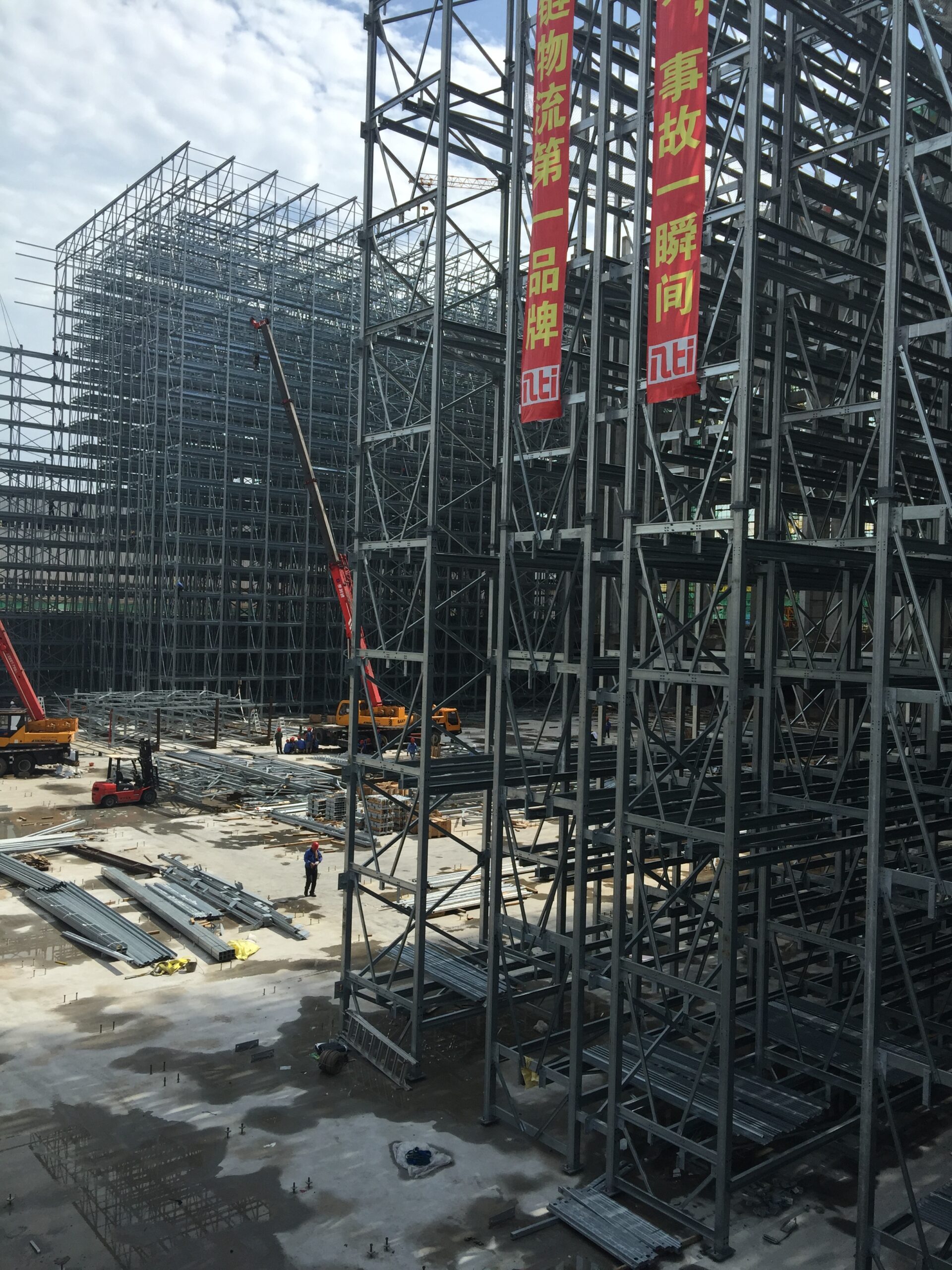

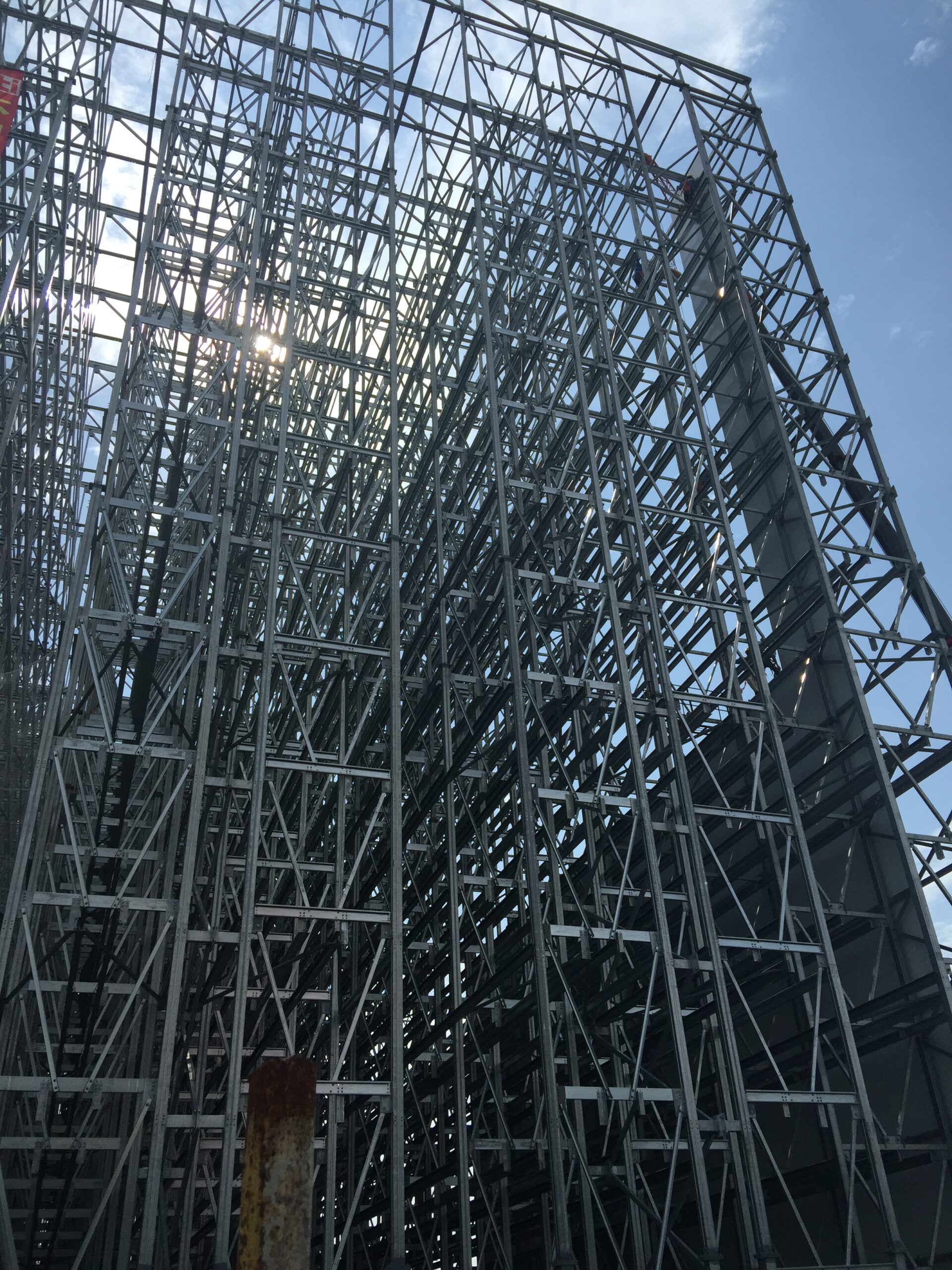

The steel racking structure under construction is designed to reach significant heights and provide exceptional storage density. The framework consists of thousands of interlocked beams, uprights, and diagonal braces, forming a rigid lattice capable of supporting heavy palletized loads while ensuring long-term stability.

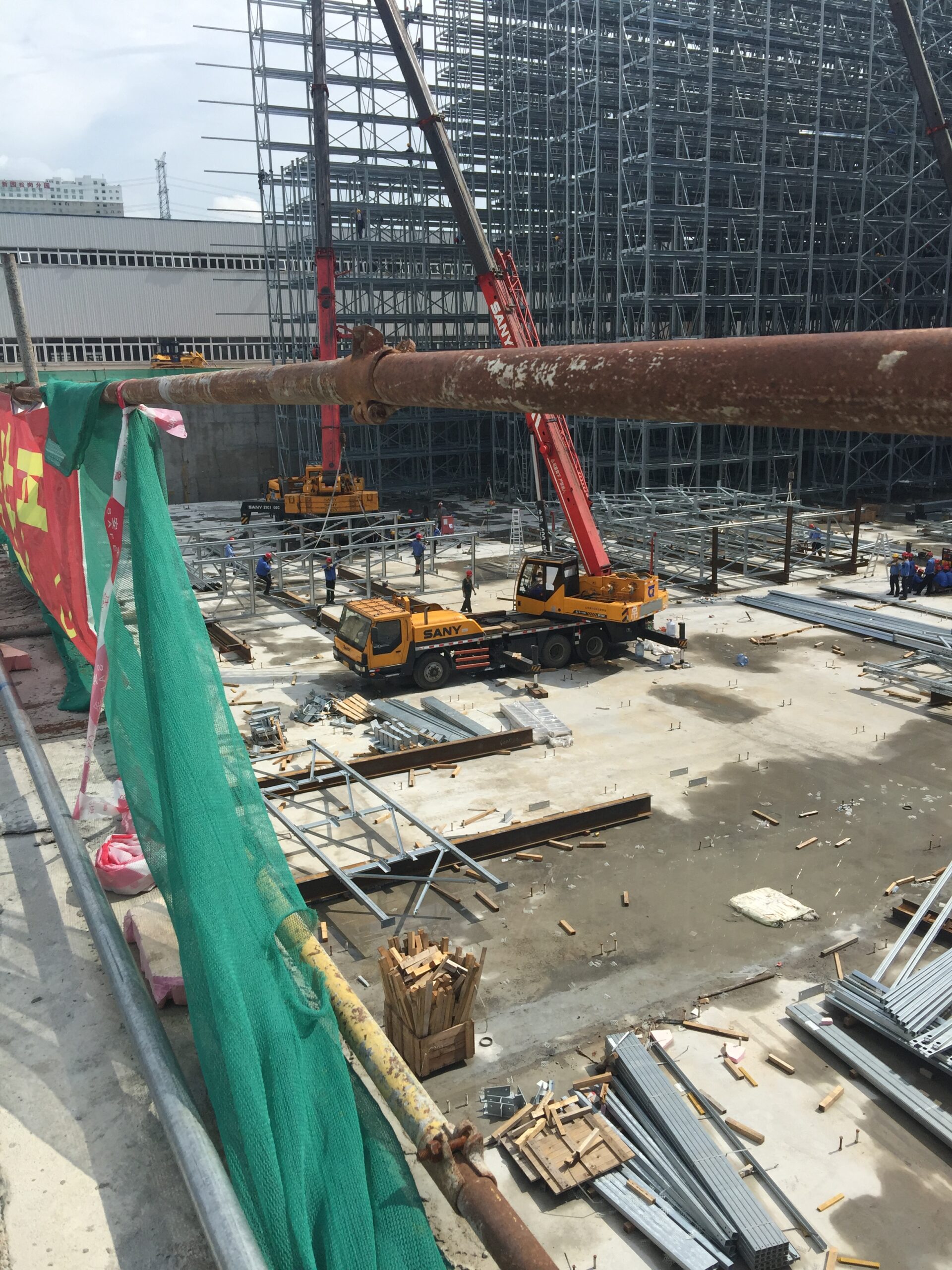

Multiple crane units, lifting platforms, and installation teams operate simultaneously across the job site, enabling efficient handling of large structural components and precise positioning at elevated heights.

This systematic approach to assembly ensures:

- High dimensional accuracy across all rack levels

- Stable structural integrity for tall, multi-deep storage lanes

- Optimized load distribution, even under continuous operational stress

Precision Engineering from Ground Up

Before vertical assembly begins, all base plates, anchor bolts, and foundational elements undergo strict alignment and leveling checks. This guarantees that the entire racking system meets engineering tolerances from the first column onward.

As the structure rises, cross-beam modules and bracing components are installed section by section. Each connection point is secured according to load-bearing standards, ensuring long-term reliability and safety. The images capture the meticulous installation process, where workers operate within the steel framework to verify alignment, tighten structural joints, and prepare the system for subsequent mechanical integration.

Designed for Modern Automated Warehousing

Once completed, this racking system will support advanced logistics operations such as:

- Automated Storage and Retrieval Systems (AS/RS)

- High-bay pallet storage

- Automated guided vehicles and conveyor interfaces

- Real-time inventory management platforms

The narrow aisles, high-rise layout, and perfectly aligned pallet positions all reflect a design optimized for fast, accurate, and automated material flow.

A Foundation for Future Logistics

This project is more than a construction site—it is the foundation of a future-ready warehouse. With its robust steel framework, scalable configuration, and compatibility with leading automation technologies, the system will deliver:

- Higher storage density

- Improved space utilization

- Faster operational throughput

- Lower long-term operating costs

As global supply chains accelerate their transition toward intelligent logistics, such high-rise racking systems are becoming essential infrastructure for manufacturing, distribution, and e-commerce fulfillment.

StorLogi

StorLogi