StorLogi Automated Warehousing System: Smart Innovation Leading a New Era in Logistics

724StorLogi’s automated warehouse system boosts logistics efficiency through smart storage, space optimization, and full automation.

View detailsSearch the whole station

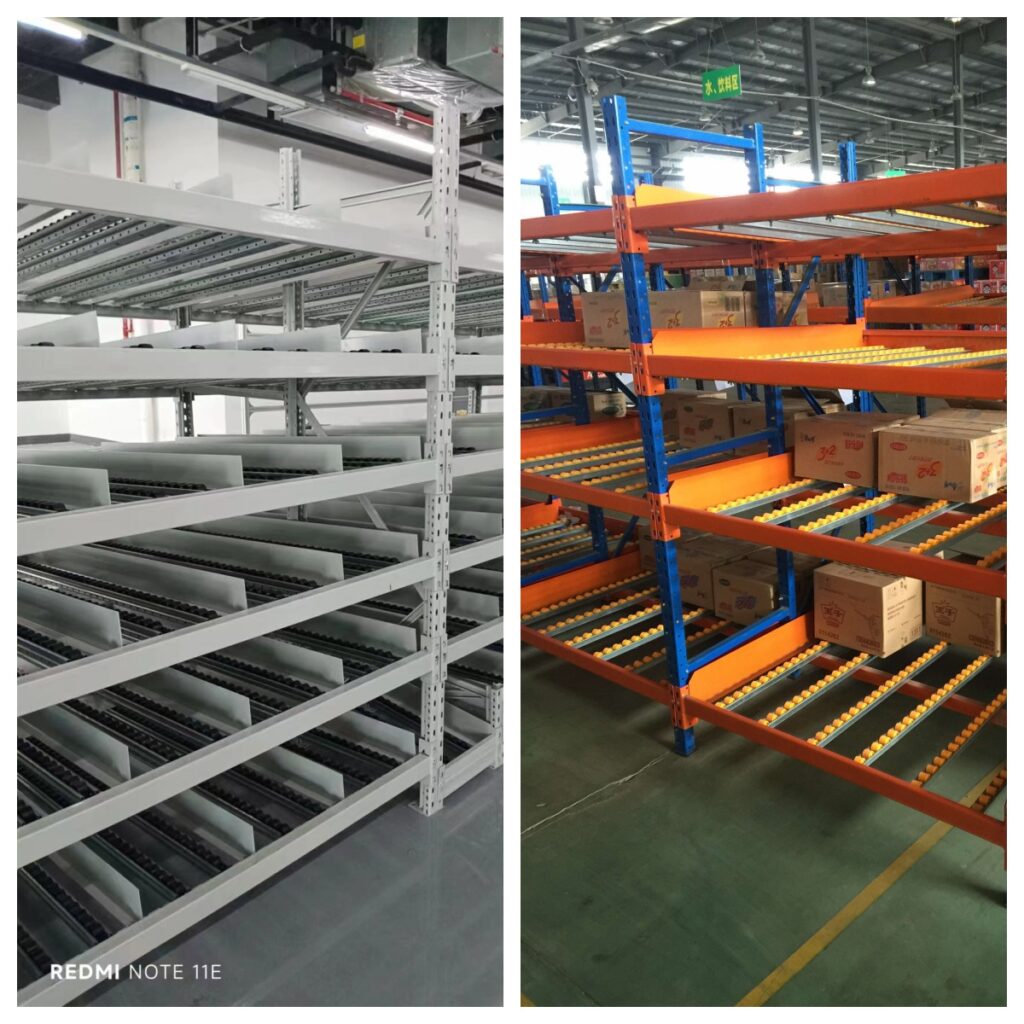

In modern warehouse and logistics operations, achieving high-density storage, rapid material flow, and precise inventory control within limited space is critical for driving down costs and boosting productivity. Drawing on years of experience in the storage equipment industry, StorLogi has introduced its innovative Flow Rack system. Combining intelligent design with outstanding performance, these racks have become the ideal solution for manufacturers, logistics providers, and retailers seeking to optimize warehouse management. This integrated storage solution—intelligent, efficient, and flexible—is reshaping the benchmark for rack value through technological innovation and adaptable applications.

1. Gravity‑Driven First‑In, First‑Out (FIFO)

StorLogi’s Flow Racks use roller-based aluminum flow rails set at a slight incline (typically around 3°). When cartons or totes are placed on the upstream end, gravity causes them to glide smoothly to the downstream pick face, automatically enforcing FIFO inventory rotation. This design prevents stock buildup and is especially vital for perishable goods—such as in food and pharmaceutical sectors—ensuring items closest to expiration are picked first and minimizing waste.

2. Adjustable Shelf Pitch

Each level’s rail spacing can be adjusted in 50 mm increments, with fine‑tuning available via clip‑on shims. We recommend setting the minimum pitch to the container height plus 200 mm, but customers can tailor spacing in any 50 mm multiple to suit their requirements. This flexibility accommodates a wide range of load sizes—from small components to large totes—maximizing the utility of each rack bay.

3. Compatibility with Multiple Container Types

Common flow containers—including plastic totes, parts bins, and cartons—slide effortlessly on StorLogi’s Flow Racks. This versatility makes them suitable across diverse industries, enabling seamless storage and retrieval regardless of packaging format.

1. Maximized Space Utilization

Compared with standard static shelving, Flow Racks’ dense storage design can boost warehouse space utilization by over 60%. For operations constrained by footprint but requiring high capacity, this translates directly into lower real estate and handling costs.

2. Streamlined Pick and Replenishment

As products roll to the pick face automatically, staff spend far less time searching through aisles. Picking speeds can improve by up to tenfold compared with conventional racks—especially valuable in high‑throughput distribution centers, where every second counts in order fulfillment.

3. Integrated Information Management

Flow Racks can be equipped with electronic shelf labels for digital inventory control. Real‑time data on item location and stock levels supports faster cycle counts, proactive replenishment, and end‑to‑end visibility—elevating warehouse management from manual to fully automated.

1. Manufacturing

In automotive, electronics, and appliance plants, Flow Racks are often placed alongside production lines to store critical parts. FIFO rotation helps maintain uninterrupted throughput and ensures component freshness, driving quality and efficiency on the line.

2. Logistics & Distribution

High‑velocity distribution centers benefit immensely from Flow Racks’ reduced travel distances and instant availability at the pick face. Fast, accurate picking meets tight delivery windows and supports same‑day fulfillment strategies.

3. Retail

In supermarkets, convenience stores, and retail backrooms, Flow Racks facilitate both display and storage. Products glide forward as stock is depleted, enabling automatic front‑face replenishment that delights customers and reduces labor for staff.

4. Cold Storage & Cold Chain Logistics

In temperature‑controlled environments, Flow Racks minimize air exchange and energy loss while ensuring effective FIFO handling of chilled and frozen goods. Their robust, low‑maintenance design thrives under strict hygiene and thermal regulations.

StorLogi’s Flow Rack system—anchored by innovative engineering, tangible performance gains, and versatile application—stands as the premier choice for businesses looking to revolutionize their warehouse operations. With a customer‑centric approach, StorLogi not only delivers world‑class rack products but also partners with clients to develop tailor‑made solutions that align with industry specifics and site conditions. Whether you’re a manufacturing powerhouse or a logistics‑intensive distributor, choosing StorLogi Flow Racks means embracing a smarter, more efficient warehousing future.

StorLogi’s automated warehouse system boosts logistics efficiency through smart storage, space optimization, and full automation.

View detailsStorLogi Flow-Through Racks deliver a gravity-powered FIFO shelving solution that speeds up picking by over 30%, offers instant inventory visibility, and features modular customization plus end-to-end support to boost warehouse efficiency for e-co...

View detailsStorLogi’s modular, high-strength steel mold racks optimize warehouse space, enhance safety, and streamline mold management for manufacturers—customizable solutions from design to installation.

View detailsExplore storlogi's innovative AGVs with laser/QR code navigation, autonomous operation & smart solutions for warehousing efficiency.

View details 0

0loading...