Unlocking Efficient Warehousing: Introducing Storlogi’s Shuttle Racking System

645Storlogi Shuttle Racking System Leader in Intelligent Warehouse Solutions ,High - density Storage ,Automated Operation /,Modular Design

View detailsSearch the whole station

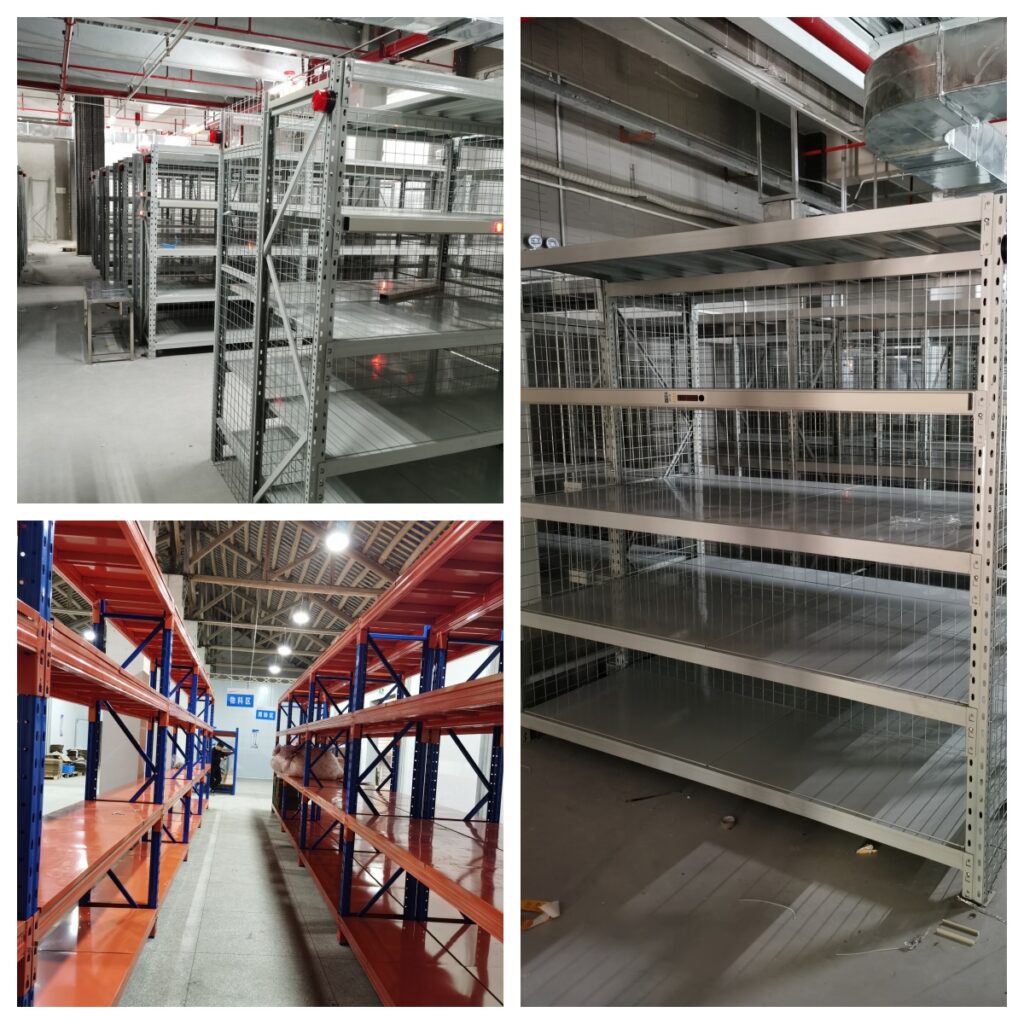

In the field of warehousing and logistics, the choice of racking directly impacts space utilization, storage safety and operational efficiency. As an industry leader, StorLogi’s Medium-Duty Beam Racking combines outstanding performance, thoughtful design and a wide range of configurations to deliver premium storage solutions for countless businesses.

一、Product Features: Professionalism in Every Detail

(a) High-Strength Load Capacity & Stability

The main frame of StorLogi’s Medium-Duty Beam Racking is constructed from high-strength Q235B steel, renowned for its excellent strength and toughness. Each shelf level supports between 500 kg and 1,500 kg, easily accommodating mechanical parts, hardware tools or packaging materials of moderate weight. At each beam-upright junction, a “dual-clamp + safety pin” system boosts impact resistance by 50% over conventional connectors, eliminating looseness over long-term use and ensuring absolute security for stored goods.

(b) Flexible, Adjustable Shelf Heights

Recognizing the variety of goods sizes, shelf beams can be adjusted in 50 mm increments. Whether standard cartons, irregularly shaped components or specially packaged items, you’ll always find the ideal height. Its modular design even allows adding or removing levels locally—so you can adapt the rack to seasonal inventory fluctuations, avoid wasted space and maximize warehouse capacity.

(c) Rapid, Cost-Saving Assembly

StorLogi’s racks use a weld-free, clip-in installation method for effortless setup. Two people can assemble ten rack bays in under three hours—minimizing downtime and avoiding disruption to daily operations. Moreover, with 90% component interchangeability, expansion or relocation later reuses most parts, cutting hidden costs and boosting ROI.

二、Design Principles: The Ingenious Fusion of Mechanics & Ergonomics

(a) Structural Mechanics: Triangular Stability

Each upright features cold-rolled diamond-shaped slots. When beams engage, they form triangular supports that evenly distribute vertical loads in accordance with triangle stability principles—so even at full capacity the rack remains rigid, deformation-free and wobble-free, keeping stored goods completely secure.

(b) Ergonomics: Optimized for Efficient Handling

The lowest shelf sits at 200 mm—ideal for direct forklift entry—while middle levels range from 1.6 m to 1.8 m, perfectly within the ergonomic “pick zone.” Workers can retrieve items without bending or stretching excessively, reducing fatigue, minimizing errors and speeding order-picking operations.

(c) Ventilation Design: Moisture- and Rust-Prevention

Shelves are made with punched-out decks and a 5° backward tilt. The perforations ensure air circulation to keep goods dry—especially critical for metal parts or moisture-sensitive chemicals—while the tilt prevents accidental slippage and falling, further safeguarding stored items.

三、Product Advantages: Data-Backed Performance

(a) Dramatic Space Savings

Compared to floor-stacking, StorLogi’s vertical storage racks make full use of overhead space. Field tests show the same footprint can store three times more goods, boosting space utilization by 60%. That means you can greatly increase capacity without expanding your warehouse, driving down per-unit storage costs.

(b) Significant Efficiency Gains

Standardized slot labeling plus barcode scanning reduces locating time dramatically. Inventory accuracy reaches 99.9%, and picking accuracy is equally high. Overall operations accelerate by 35%, slashing inbound/outbound cycle times and elevating throughput.

(c) Rapid Return on Investment

In a 1,000 m² warehouse with annual rent of ¥500,000, StorLogi racks can cut per-square-meter storage costs by 40%. Combined with long service life and low maintenance, payback occurs in 12 months or less—quickly unleashing financial benefits and improving cash flow.

四、Creating Value for Customers: Holistic Performance Improvement

(a) Reducing Hidden Costs

Standardized management lowers damage rates and clarifies slot coding, helping new staff learn layouts rapidly and reducing reliance on veteran employees. Robust construction also prevents collapses and related accidents, averting costly downtime and liability.

(b) Supporting Lean Production

Integrated with kanban systems, the racks enable effective FIFO inventory flow, reducing stagnant stock. Smart layout leaves ample aisles for AGV integration, paving the way for automated, streamlined operations.

(c) Long-Term Value Assurance

Backed by a 10-year lifecycle test, StorLogi racks feature epoxy powder coating with multi-stage anti-corrosion treatment achieving national Grade 2 corrosion resistance. They resist peeling and rust, offering stable, long-term service without frequent replacement fees or operational disruptions.

(c) Long-Term Value Assurance

StorLogi’s medium-duty racking has passed a 10-year lifecycle test, ensuring reliable quality. Its surface is coated with epoxy resin powder and treated through multiple processes, achieving national Grade 2 corrosion resistance. This means the racks will not peel or rust over long-term use, providing enterprises with a stable and durable storage solution. During its lifecycle, the racking system rarely needs replacement, significantly reducing costs and operational disruptions associated with equipment upgrades.

Thanks to its scientific design, outstanding performance, and notable advantages, StorLogi’s medium-duty beam racking delivers an efficient, safe, and cost-effective solution for enterprise storage needs. Whether in manufacturing, logistics hubs, or e-commerce warehousing, it adapts seamlessly to various scenarios—helping businesses improve warehouse management and enhance their market competitiveness. Choosing StorLogi’s medium-duty beam racking is choosing an efficient, intelligent, and sustainable future for your storage operations.

Storlogi Shuttle Racking System Leader in Intelligent Warehouse Solutions ,High - density Storage ,Automated Operation /,Modular Design

View detailsOptimize your warehouse with StorLogi Flow Racks—featuring gravity‑flow FIFO, adjustable rails, and digital inventory control—for a smarter, higher‑density storage solution.

View detailsIn today’s environment, where the digital economy is deeply integrated with new retail models, warehousing and logistics have become a core competitive advantage within the enterprise supply chain. As a professional provider of warehouse racking ...

View detailsIn the Industry 4.0 era characterized by the deepening of global trade and the accelerated penetration of digital technologies, the warehousing and logistics link has broken through the single attribute of traditional "goods storage and trans...

View details 0

0loading...