3. Smart Integration, Efficient Management

StorLogi actively integrates cutting-edge technologies to enable intelligent management features in its beam racking systems. Utilizing technologies such as IoT, big data, and cloud computing, companies can monitor warehouse inventory in real time. Via mobile or computer terminals, managers can view detailed information such as storage locations, inventory quantities, and inbound/outbound records—achieving visual and digital warehouse management.

The intelligent system can also use historical data and real-time inventory dynamics to accurately forecast future inventory needs, helping companies develop better procurement and sales plans, avoid overstock or shortages, reduce operational costs, and increase market responsiveness. When paired with automated equipment such as stackers or smart AGVs, and under unified control via a central computing system, the solution enables 24/7 operations, greatly reducing turnover time and improving overall warehousing efficiency.

4. Safety Protection, Reliable Assurance

Safety is paramount in warehousing. StorLogi beam racking is designed and manufactured with full consideration of safety factors. In addition to its robust structure, the racks come equipped with various safety features. For example, anti-collision bars are installed around the columns to reduce the risk of forklifts and other handling equipment damaging the structure. Drawer panels include limit pins to prevent items from sliding during storage or retrieval. Some racks are also equipped with safety locks to ensure item security—providing comprehensive protection for stored goods and safeguarding corporate assets.

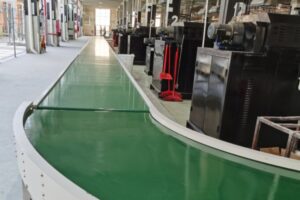

5. Wide Applications, Industry Benchmark

Thanks to their excellent performance, StorLogi beam racking systems are widely used across many industries. In manufacturing—such as automotive or machinery—they are used to store heavy components and raw materials. With intelligent identification and tracking, parts can be delivered to production lines quickly and accurately, improving efficiency and quality. In the logistics sector, distribution centers use StorLogi beam racks along with automated sorting systems for efficient item categorization and rapid processing, enhancing logistics response times. In the chemical industry, the system accommodates complex storage requirements and ensures safe, categorized storage for various chemical products. For cold chain industries, the racks can withstand low-temperature environments, ensuring the secure storage of frozen foods and pharmaceutical products.

From design and development to manufacturing, installation, and maintenance, StorLogi offers professional, full-service solutions. Skilled installation teams and strict quality management ensure that every project is tailored for maximum efficiency, safety, and durability, delivering optimal performance in real-world usage.

StorLogi

StorLogi