Flexible Conveyor System: Customized Line Logistics for Multi-Industry Efficiency

In modern intelligent manufacturing and production line logistics systems, conveyor systems are the core link connecting “equipment-process-capacity”. Based on the production characteristics of different industries, we provide end-to-end solutions from custom conveyor equipment R&D to whole-line production logistics layout. The professional adaptability is analyzed below with real-case scenarios:

1. Large-span Curved Flexible Conveyor Lines

Suitable for long-distance continuous production lines in food, daily chemical, electronics and other industries:

- Curved Steering Design: Adopts integrally formed green PU conveyor belt + curved frame to realize 90°/180° dead-angle-free material steering, adapting to the spatial layout of complex production lines;

- High-stability Configuration: The frame is made of thickened steel welding + bolt reinforcement, and the conveyor belt surface is wear-resistant and oil-resistant, supporting a material load of 10-50kg/㎡ to meet the continuous operation needs of mass production;

- Production Line Collaboration: Seamlessly connects with sorting equipment, packaging machines, etc., and realizes precise process connection with production line number marks (e.g., “Zone 2”), improving the overall line flow efficiency by more than 30%.

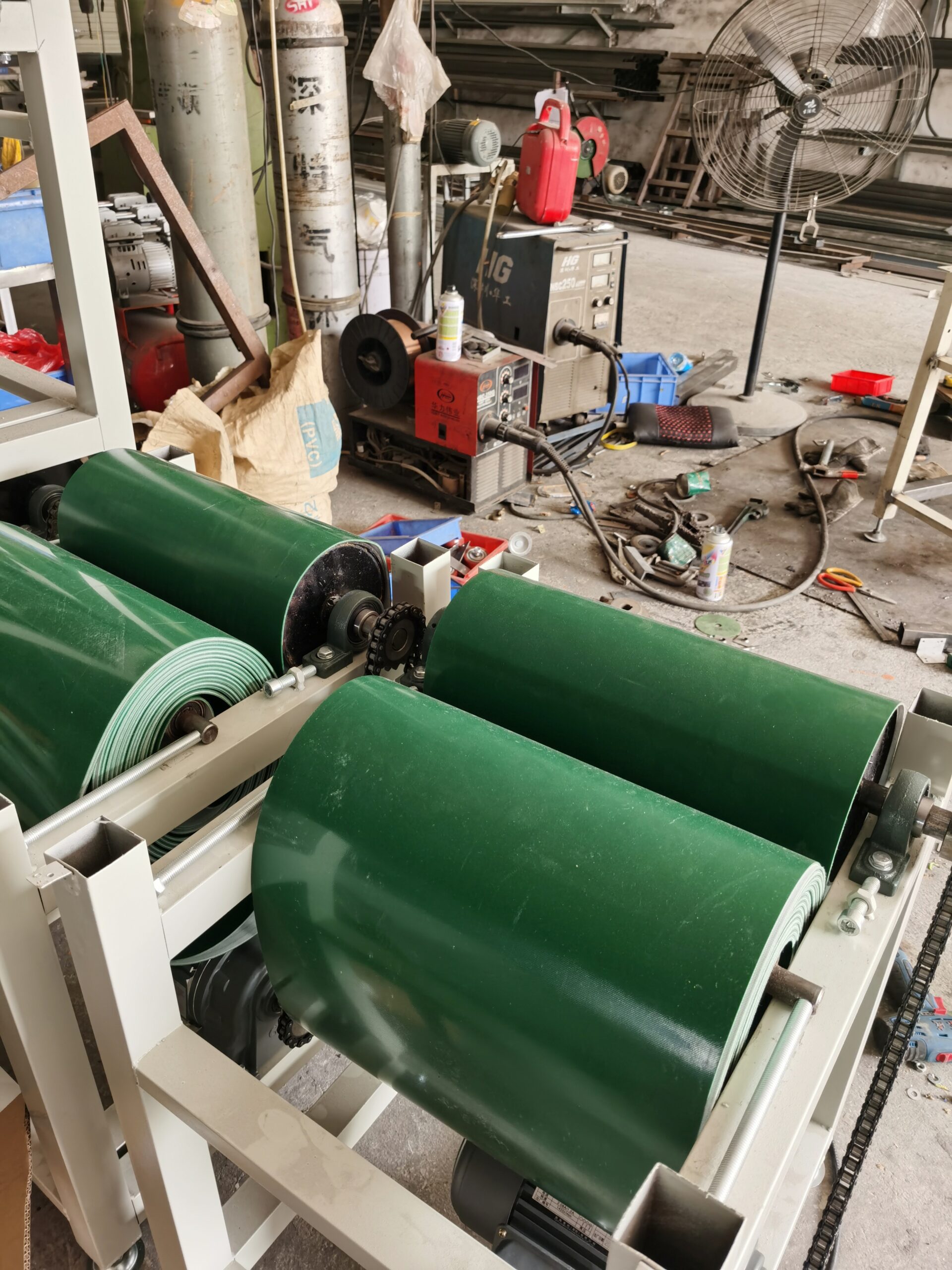

2. Small Modular Conveyor Units

Adapted for short-distance material transfer in workshops of precision electronics and small parts:

- Modular Assembly: Uses aluminum profile frame + independent power unit, which can be flexibly spliced according to workshop space to quickly adjust the conveying path;

- Power System Optimization: Equipped with chain-driven motor + speed controller, the conveying speed can be adjusted between 0.5-3m/s to adapt to the rhythm needs of different processes;

- Protection and Compatibility: The conveyor belt surface is anti-slip treated, and the frame reserved interfaces can be expanded with baffles and positioning sensors to meet the anti-offset and precise positioning needs of precision materials.

3. Production Line Supporting Conveyor Systems

Serving customized production lines in apparel, home furnishing and other industries:

- Material Adaptation Design: For irregular materials such as mannequins and large semi-finished products, adopts wide conveyor belt + adjustable frame height design to ensure stable material conveying;

- Warehouse-Production Line Connection: The end of the conveyor line can be connected to the shelf storage area, and realizes seamless “storage-to-production line” flow with palletized materials (e.g., conveyor belt rolls, metal rollers);

- Flexible Expansion Capability: The frame adopts a quick-install structure, which can quickly add conveyor units with the production capacity upgrade, reducing the time and cost of production line transformation.

With “scenario-based customization + full-cycle service” as the core, our conveyor systems cover equipment R&D, layout design, installation and commissioning, creating an “efficient, stable and scalable” production line logistics system for customers in various industries, helping enterprises achieve continuous improvement of production efficiency.

StorLogi

StorLogi