In industries such as manufacturing, building materials circulation, and engineering infrastructure, the warehousing management of long materials—including profiles, pipes, plates, and cable reels—has long been an efficiency bottleneck in the supply chain. Floor stacking leads to space wastage, manual handling increases material loss, and inventory disorganization slows down turnover. As a heavy-duty storage equipment dedicated to long materials, cantilever racking is reconstructing the warehousing logic of such scenarios through customized structural design, heavy-load capacity, and high-efficiency operation design, realizing a transformation from passive storage to active management.

I. Underlying Product Logic: Structure Design Centered on Material Form

The core storage pain points of long materials lie in their excessive length, irregular shape, and concentrated weight. The structural design of cantilever racking is a targeted solution to these pain points:

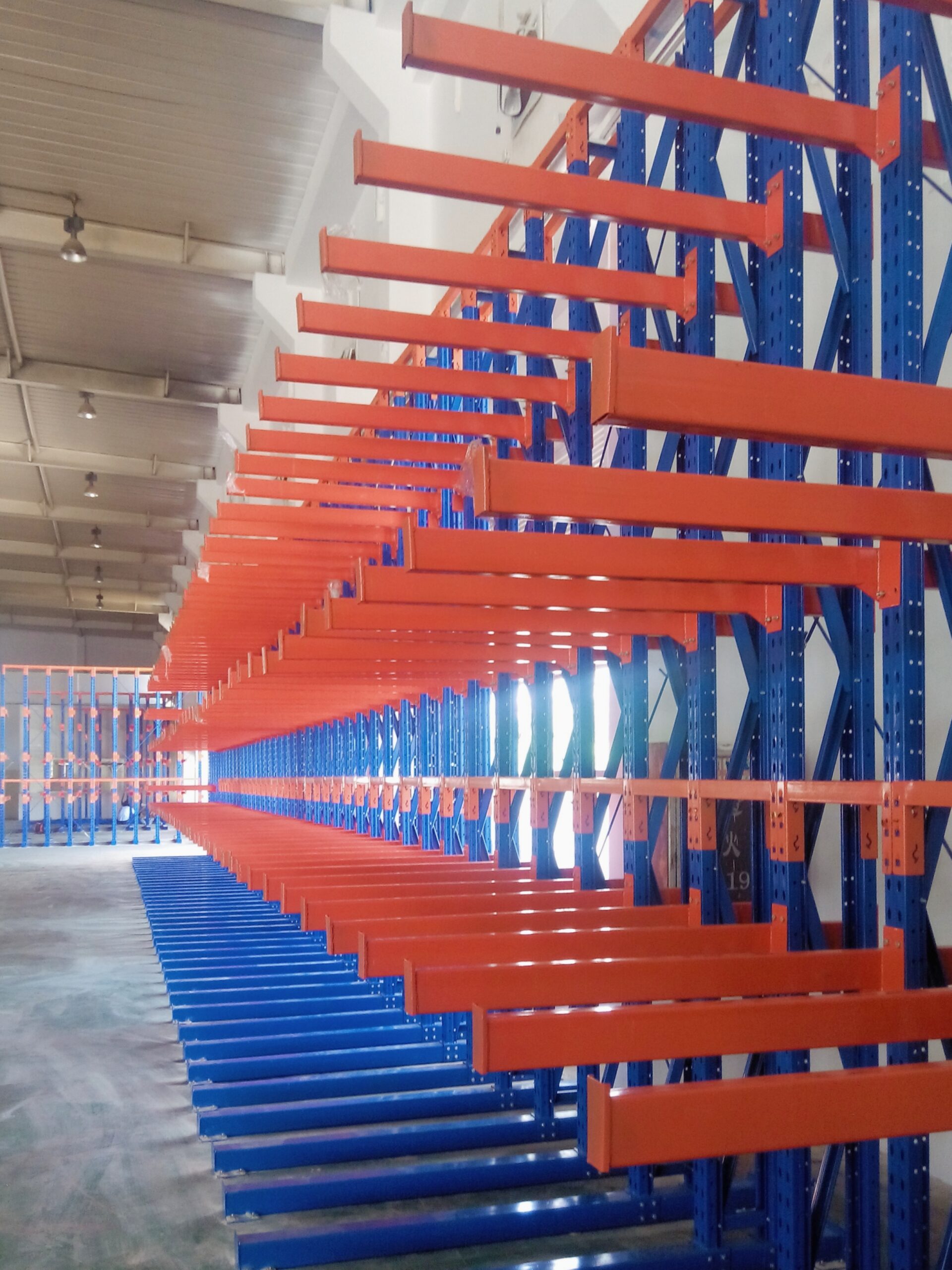

Cantilever Structure: Boundary-Free Storage for Long Materials

Different from the enclosed compartments of traditional beam-type racking, cantilever racking adopts outward-extending cantilever beams as storage units. The length can be customized from 1 meter to 8 meters or even longer, allowing long materials to be placed in layers in their original form without cutting to fit. This avoids material loss and cost increases caused by cutting.

Modular Combination: Flexible Layout for Diverse Scenarios

The racking adopts a modular structure consisting of columns, cantilevers, and bases. It can be configured as single-sided or double-sided cantilevers according to warehouse conditions:

- Single-sided cantilevers : Utilize warehouse wall space, suitable for wall-mounted storage in small and medium-sized warehouses.

- Double-sided cantilevers : Occupy space on both sides of the aisle, offering higher storage density and ideal for bulk storage in large logistics centers.In addition, the number of cantilever layers (2–6 layers) and layer spacing (300–1500mm) can be adjusted as needed to match the height and access frequency of different materials.

Heavy-Load Performance: Structural Strength for Heavy Materials

The core components are made of Q235B carbon structural steel, connected via a dual method of welding and bolt fixing, combined with thickened bases. A single cantilever has a rated load capacity ranging from 500kg to 2000kg. The entire racking system can stably bear heavy materials such as steel, copper, and heavy pipes, with structural deflection during long-term use complying with the safety standards specified in GB/T 28576-2012 Storage Racking Use Specifications.

II. Practical Value Implementation: Three-Dimensional Upgrade in Space, Efficiency, and Cost

Taking the warehousing upgrade project of a large building materials trader as an example, its stored products include 6-meter aluminum profiles, 8-meter PVC pipes, and 3-meter-wide plates. The comparison before and after the upgrade intuitively reflects the value of cantilever racking:

Space Dimension: From Extensive Stacking to Intensive Utilization

- Before upgrade : Long materials were stacked on the floor, occupying 400㎡ of warehouse space with a storage capacity of only 1200 tons, resulting in a space utilization rate of less than 40%.

- After upgrade : 5-layer double-sided cantilever racking with 6-meter-long cantilevers was adopted, achieving a storage capacity of 1500 tons in only 180㎡. The space utilization rate was increased to 85%, while 220㎡ of space was freed up for storing new product categories.

Efficiency Dimension: From Manual Dependence to Mechanized Operation

- Before upgrade : Retrieving materials required 2–3 workers to operate cranes or manual forklifts, taking approximately 20 minutes per order for locating, accessing, and retrieving goods. The daily order processing capacity was only 30 orders.

- After upgrade : With the use of reach stackers, a single worker can complete the entire process of positioning, accessing, and returning goods independently. The time per operation is shortened to 3 minutes, and the daily order processing capacity is increased to 120 orders, representing a 300% improvement in operational efficiency.

Cost Dimension: From Hidden Losses to Controllable Management

- Before upgrade : Material deformation and collision damage caused by stacking resulted in a loss rate of about 5%, with monthly labor costs for manual handling reaching 80,000 yuan.

- After upgrade : Layered storage prevents material extrusion, reducing the loss rate to 0.5%. Mechanized operations cut labor deployment by 60%, lowering monthly labor costs to 32,000 yuan, which translates to annual cost savings of over 570,000 yuan.

III. Customized Service System: Precise Matching of Racking to Warehousing Scenarios

The core value of cantilever racking lies in its non-standard customization capability. The service process of professional suppliers is the key to realizing this value:

Pre-Survey: Accurate Collection of Scenario Data

On-site measurement of warehouse length × width × height, operation aisle width, and forklift turning radius is conducted. Meanwhile, data such as material length, weight, and daily access frequency are collected to form a warehousing scenario analysis report.

Solution Design: In-Depth Adaptation of Structure and Function

Based on survey data, the cantilever length, number of layers, and load-bearing parameters of the racking are designed. Additional functions are developed according to enterprise needs:

- Anti-slip stoppers installation : Prevent rolling of circular pipes and cable reels.

- Intelligent label holders configuration : Integrate with WMS (Warehouse Management System) to achieve visual inventory management via barcode scanning.

- Protective columns addition : Avoid collisions with the main racking structure during forklift operations.

Installation and Acceptance: Dual Assurance of Safety and Standards

Installation is carried out on-site by certified teams. After installation, no-load and full-load tests are performed to ensure that racking deflection and stability meet national standards. A racking operation manual is also provided, specifying load limits, operation specifications, and other precautions.

For enterprises with intensive long-material storage needs, warehousing is not a cost center but an efficiency hub. The value of cantilever racking goes beyond space saving—it accelerates supply chain turnover through structural adaptation, operational efficiency improvement, and inventory control.

StorLogi

StorLogi