From “Traditional Shelving” to “Smart Shelving”: The Three Things We Got Right

In the wave of transformation sweeping the warehousing industry—from labor-intensive operations to intelligent automation—StorLogi has consistently stood at the forefront of technological innovation. By deeply analyzing the pain points of enterprise warehousing and pursuing relentless innovation, we have achieved a leap from traditional storage racks to fully smart shelving. Below, we reveal the three core strategies that have helped numerous companies boost their warehousing efficiency and management capabilities.

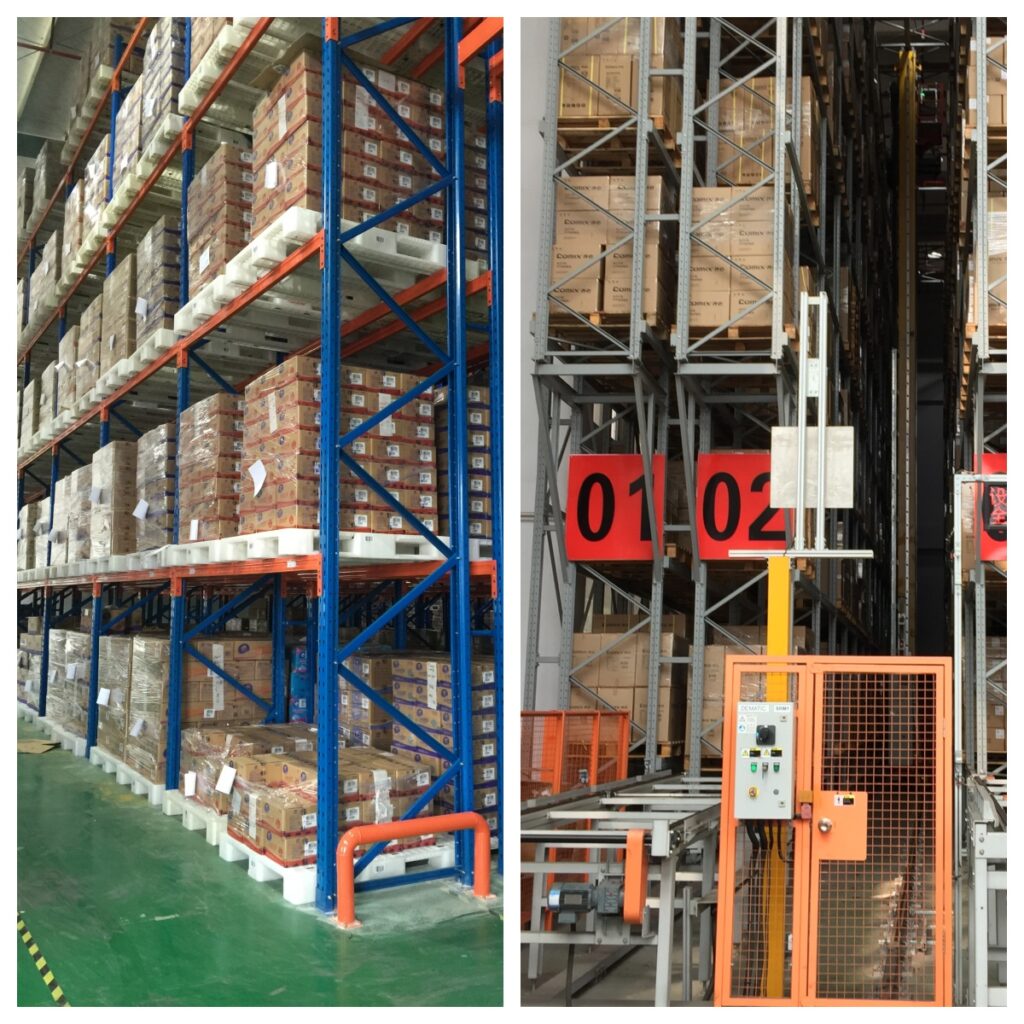

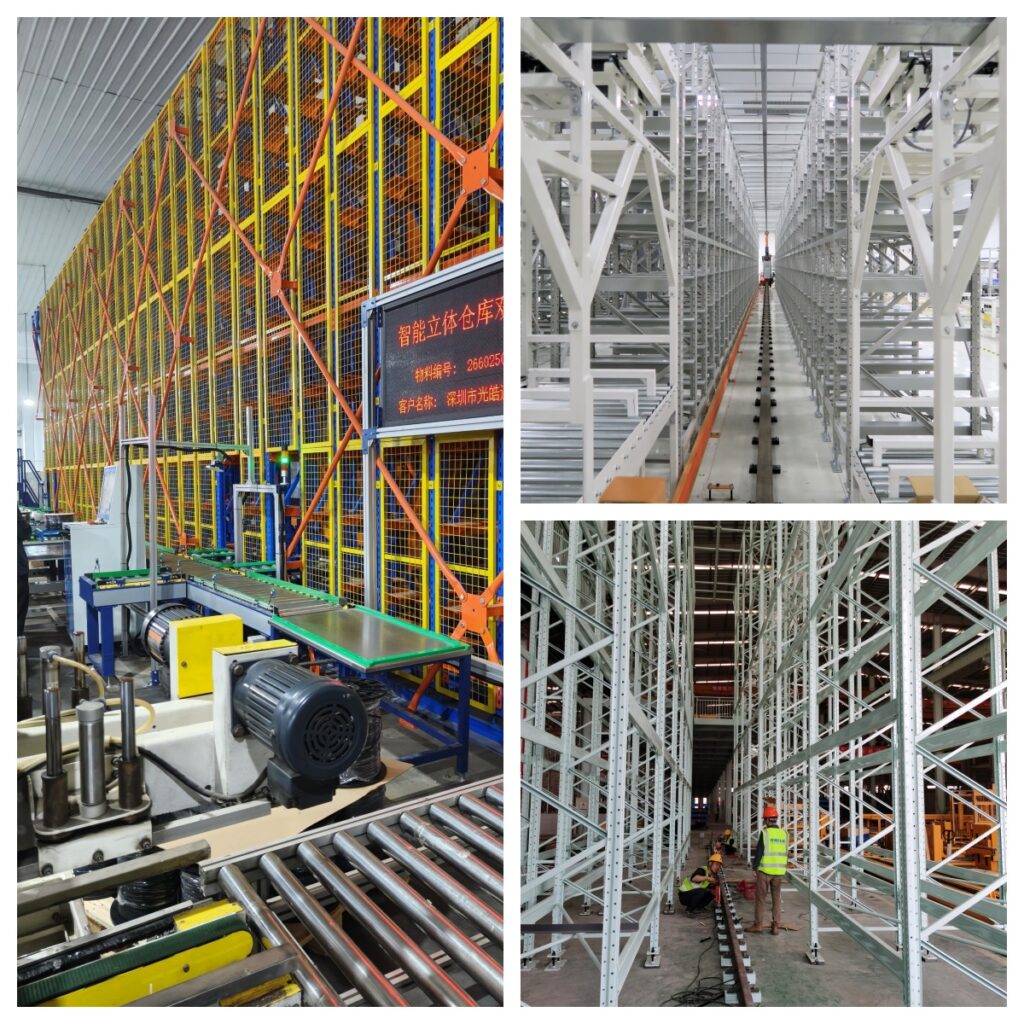

1. Hardware Upgrade: From “Steel Frames” to “Intelligent Carriers”

Traditional shelving merely provides physical support for goods, with a single, limited function that falls short of today’s demands for high-efficiency warehousing. StorLogi broke through this limitation by transforming shelves from passive storage tools into active carriers within an intelligent warehousing system.

RFID-enabled inventory

Every bin on a StorLogi smart shelf is equipped with an RFID tag and integrated smart chip, enabling automatic identification and precise location tracking of goods as they move in and out. What once required manual, item-by-item counting can now be scanned in seconds—boosting inventory audit efficiency by up to 90%.

Real-time load monitoring

Weight sensors embedded in each shelf continuously monitor its load. If capacity is ever exceeded, the system instantly issues an alert, effectively preventing shelf collapse accidents. For example, a chemical manufacturer that adopted StorLogi smart shelving was able to avert potentially dangerous overloads, ensuring stable, safe operations.

Eco-friendly, high-strength materials

StorLogi uses Q355B high-strength steel to maintain load capacity while reducing material usage by 15%, cutting production costs and lowering carbon emissions by 20%. A phosphate-free, environmentally friendly coating line meets national first-class wastewater standards, earning our factory a “Green Factory” certification. This approach guarantees shelf durability while demonstrating our commitment to sustainable development.

2. Software Integration: Deep Collaboration among Shelving, WMS & Automation

Traditional racks operate in isolation from Warehouse Management Systems (WMS) and automation equipment, causing information bottlenecks and low throughput. StorLogi addressed this by creating a fully integrated ecosystem that links smart shelving to your WMS and automated machinery.

Seamless WMS connectivity

Data from every shelf location syncs in real time with the WMS. The system analyzes live inventory data and warehouse layout to generate optimal storage plans, increasing space utilization by 35%. During inbound and outbound operations, shelf data guides pickers or robots directly to the right bin—eliminating wasted search time.

Automated equipment synchronization

StorLogi smart shelving communicates with AGV robots, stackers, and other automated devices. Upon receiving a pick or put-away command, AGVs navigate autonomously to the specified shelf, retrieve the item, and deliver it to its destination—enabling a “goods-to-person” workflow. One major e-commerce warehouse using this integrated solution now runs 24/7 unmanned, dramatically boosting daily order throughput while slashing labor costs.

3. Continuous Innovation: Customer-Driven Product Iteration

StorLogi understands that smart shelving is not a one-time project; only by relentlessly innovating—and listening to customer needs—can we maintain a competitive edge.

Industry-specific features

Through extensive research across sectors, we identify unique warehousing challenges and tailor our offerings accordingly. For the food and pharmaceutical industries—where expiry tracking is critical—we developed smart shelves with expiry-warning LED indicators, integrated with the WMS to automatically alert staff when items approach their shelf life, ensuring strict FIFO (First-In, First-Out) compliance. For space-constrained SMEs, our modular mezzanine smart shelves optimize vertical space while retaining full digital management capabilities.

Robust feedback loop

We’ve established a comprehensive customer feedback mechanism, using real-world insights to refine both hardware and software. From enhancing WMS features to improving shelf structure, each iteration targets greater efficiency and ease of use—so our clients continually benefit from cutting-edge warehousing solutions.

By focusing on these three pillars—hardware upgrades, software integration, and continuous, customer-driven innovation—StorLogi has delivered smarter, safer, and more efficient warehousing solutions to enterprises. Looking ahead, StorLogi will continue to delve into intelligent warehousing technologies and explore novel models, empowering more companies to achieve transformational gains in their warehousing management and usher in a new era of smart logistics.

StorLogi

StorLogi