一、Core Principles of Automated Warehousing Technology

The rise of automated warehousing systems addresses the limitations of traditional flat-warehouse models. These conventional systems often suffer from low space utilization, inefficient operations, and complex manual management. In contrast, automated warehouses use vertical space to dramatically increase storage density. Their key principles include:

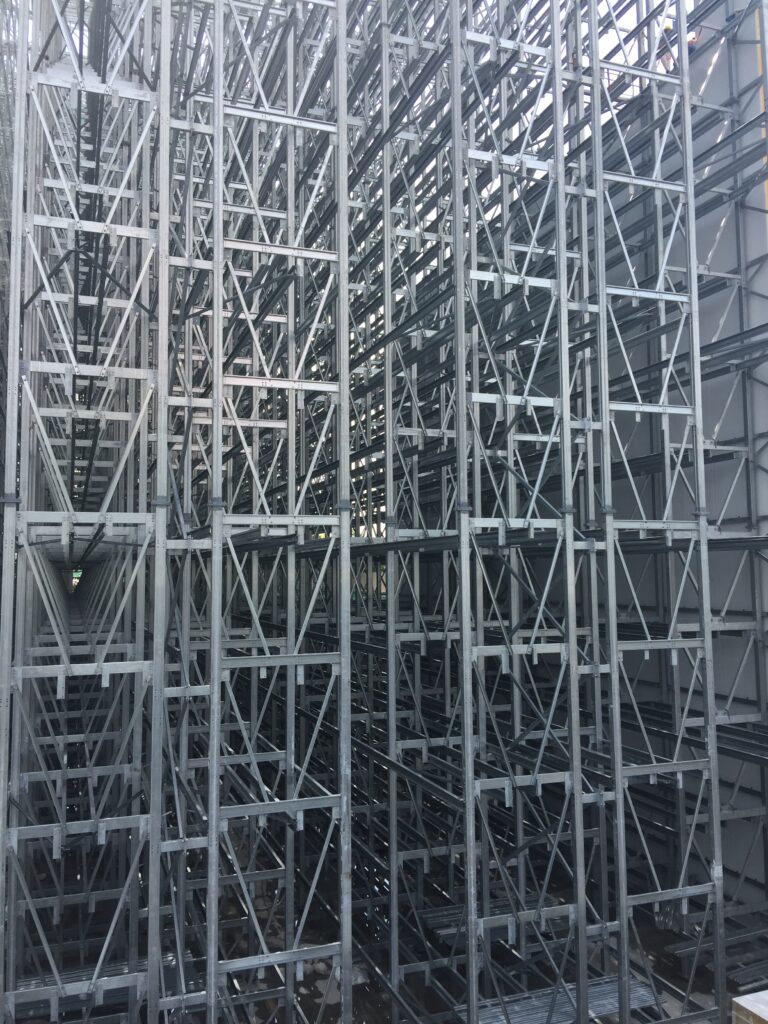

1.High-Rise Racking Design:

By constructing multi-level racking systems, vertical space is maximized, allowing warehouses to store significantly more inventory within the same footprint. Logically, increasing the number of vertical storage levels directly multiplies the total storage capacity.

2.Automated Transport and Stacking:

Integrated systems including automated stacker cranes, conveyors, and robotic handling equipment enable fully automated inbound, outbound, and internal handling processes. By reducing manual operations and human error, the system ensures both high efficiency and reliability.

3.Intelligent Management Systems:

Paired with advanced Warehouse Management Systems (WMS), automated warehouses offer real-time inventory tracking, smart scheduling, and data-driven decision-making. Technologies such as IoT and big data analytics optimize logistics flows and significantly enhance supply chain responsiveness.

二、StorLogi’s Advantages and Application Scenarios

Based on case studies and technical analysis, StorLogi’s automated warehouse solutions demonstrate outstanding performance in various areas:

1.Maximized Space Utilization:

Through multi-tier shelving and efficient layout planning, storage density can be increased by 2 to 5 times. This is particularly valuable in regions with high land costs, enabling businesses to meet growing market demands without expanding their physical footprint.

2.Automated Workflows for Higher Productivity:

With advanced automation, key operations such as storage, sorting, and retrieval are handled with minimal human intervention. Compared to traditional manual systems, automated workflows significantly reduce processing time while improving accuracy and consistency.

3.Data-Driven Smart Management:

StorLogi’s systems leverage real-time data monitoring, predictive analytics, and precision scheduling to optimize inventory levels and reduce waste. Logically, such data-centric models enhance decision-making, streamline processes, and promote operational transparency.

4.Flexible Design for Future Growth:

StorLogi’s systems are modular and scalable, designed to adapt to business growth and seasonal demand fluctuations. This future-proof design ensures long-term usability, allowing enterprises to remain agile in dynamic markets.

StorLogi

StorLogi